High-effective UVMILK® milk filter

Removes the milk from mechanical impurities, rises the milk grade,

saves money and reduces the production expenses.

- Rise in price per one liter of milk due to the higher milk grade.

- We produce High-effective milk filters in strict compliance.

- Dairy plants can buy dirty raw product, filter it and receive a good quality final product.

- Dealers buy cheap milk, filter it and resell it to dairy plants.

- Reduces up to 98% of mechanical impurities

- Reduces the bacteria and acidity level.

- Increases the heat-resistance and expires the shelf life.

- Improves the color, smell and taste of the milk.

connection in the food industry.

That is why we use

clamp connection.

housing and prevents milk bleeding

of connection: clamp,

DIN, SMS and hose.

the filter housing prevents

the accumulation

of dirt and bacteria.

stainless steel. Inside welded

seams are polished.

within a minute

- No need in extra staff.

- No expenses on repair and maintenance of the equipment.

- No electricity consumption.

- No losses of milk in comparison to centrifuges and sock filters.

- Prevents the milk stone growth.

- Prevents the breakdowns of equipment such as milk meters, flowing coolers, milk cleansers, bactofuges and separator machines.

- Extends the equipment service life.

The filter cartridge

Is made of multi-layered polypropylene that retains

dirt and bacteria and passes through molecules of milk

98%

5microns

in size

120 layers

protects the milk from different contaminations

- mastitis materials

- suspended materials and burnings

- feculence

- burnt sugar

- yogurts

- condensed milk

- boiled butter

- nonconforming ice-cream

What kind of filter is better?

We compare different types of milk filters

in order to set up their advantages

and disadvantages.

|

UVMILK®

|

Cotton sock filter

|

Sand filter

|

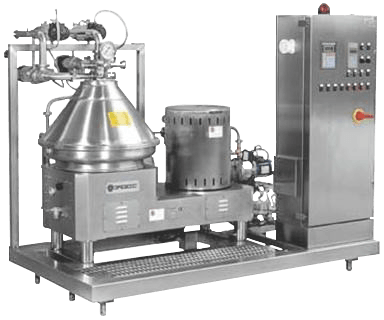

Separator

|

Bactofuge

|

|

|---|---|---|---|---|---|

| Purification of mechanical impurities | Up to 98% | Up to 50% | Up to 50% | Up to 50% | Up to 50% |

| Reduction of bacteria level | yes | yes | no | no | yes |

| Filter mesh size | 5 micron | 50 micron | 50 micron | - | - |

| Rise of milk grade | yes | no | no | no | no |

| Rise in price for 1 liter of milk | yes | no | no | no | no |

| Loss of fat | no | no | 0.5 | 0.5 | Up to 1% |

| Looses of milk | no | 2% | no | 3% | 5% |

| Extra staff for maintenance | no | no | yes | yes | yes |

| Extra staff for changing filters during the milking | no | yes | no | no | no |

| Beneficial bacteria in the milk after filtration | yes | yes | yes | yes | no |

| Filtering principle | multilayer | one-layered | milk is passed through the sand | centrifuge | centrifuge with pausterization |

| Simply installed and used | yes | no | no | no | no |

| Availaibility | yes | yes | no | no | no |

Respuestas a las preguntas

- How can the UVMILK® Filter purify cold milk?

- Where should UVMILK® Filters be installed?

- What is such price for the UVMILK® Sock Filter based on?

- How does the UVMILK® Filter affect the reduction of the somatic cell count in the milk? Reduction of bacterial numbers?

- How much do UVMILK® Filters cost?

- What is the clamp connection of the housing?

- Is the UVMILK® Filter likely to bring down the fat content?

- How can a UVMILK® Filter improve the grade?

- Why should I replace a UVMILK® Filter after milking?

- Is there a risk that a UVMILK® Filter would be clogged immediately and the pump would burn?

- Can you send the filters for trial without payment?

- Can one install a UVMILK® Filter to pump out milk from the cooler?

- They don’t pay us any extras for the grade, why should we filter the milk?

- What is the difference between UVMILK® Filters and its analogs?

Cold milk is not very different from warm milk in its structure. During the filtration of cold milk a fat globule also preserves its plasticity, and the specific structure of the filtering element allows the fat to pass and captures the dirt. Thus, UVMILK® Filters purify cold milk just as they do warm milk removing up to 98% of mechanical impurities, lowering the quantity of somatic cells and bacterial numbers, as well as retaining coarse clinical mastitis products.

The best solution would be to install a UVMILK® Filter on warm milk, i.e. before the cooling tank, because the earlier the milk is filtered, the more dirt the filter will retain before it has the time to dissolve, for the dirt, like sugar, can dissolve with time. But the filter can also be installed at any part of the process chain, including behind the cooling tank.

The UVMILK® Sock Filter cannot be compared to traditional cloth filters, because its main material is food-grade polypropylene. The filter has a multilayer structure which means that it retains not only 98% of mechanical impurities, but also mastitis products. One UVMILK® Sock Filter is enough for 1 milking operation, while, on average, it takes 3 to 4 sock filters.

Reduction of bacterial numbers is achieved by the multilayer structure of the UVMILK® Filter which retains up to 98% of mechanical impurities starting from the size of 5 μm. And, as is known, a dirty medium favors bacterial growth, consequently, if there is no dirt, there will be no medium for bacterial growth. Reduction of the somatic cell count is achieved due to the fact that the filter retains the mastitis products.

UVMILK offers a large variety of filters. The price depends on the filter’s type and capacity. The price of UVMILK® Milk Filters starts at 30 rubles. The production cost of filtration of 1 liter of milk is just over 1 kopeck.

Using threaded connection in the dairy industry is prohibited worldwide as the slots of the thread accumulate dirt resulting in bacteria propagation. CLAMP connection is a clamping device that ensures convenient and quick assembly/disassembly of pipe joints (fittings, valves, pipes) which is important in food and pharmaceutical industries where frequent disassembly of the pipeline for cleaning and disinfection purposes is requisite.

When fully assembled, the clamp connection consists of three parts:

- two identical nozzles for welding

- binding clip

- gasket

UVMILK® Filters are specifically designed for milk purification so the fat content remains the same after the filtration. A decline in fat content occurs when water filters and fake filters are being used.

UVMILK® Filters remove 98% of mechanical dirt from the milk, as well as retain clots of mastitis. Which means that the milk will be free from the environment for the bacteria to breed in which affects the bacterial numbers. And, as the mastitis products are retained, the somatic cell count will likewise go down. Milk tests before filtration and after filtration revealed a drop up in terms of bacterial numbers and somatic cells.

After the filtration a large amount of dirt is retained on the cartridge which accumulates bacteria that breed exponentially so if you keep the filter in the housing for the evening milking all the bacterial colonies will end up in the milk as the milk passes through the filter. As a result, your bacterial numbers will go above the norm.

UVMILK® Filters are manufactured in strict compliance with the manufacturing process, they go through a 3-stage quality control procedure that is why there are no risks in operation. Our engineers will select an appropriate filter for you and the system will work without failures.

Yes, we can send the filtering elements to you for trial free of charge. To do the trial you would need a stainless steel housing.

UVMILK® Filters should, preferably, be installed on warm milk lines, but if this is not an option you can mount the filter to pump out milk from the cooler. Ideally, to achieve the best possible result, UVMILK® Filters should be mounted before and behind the cooling tank as mechanical impurities might get into the milk from the tank.

If you consistently get the high-grade milk, it means that the company is trying to develop and keeps its reputation at a high level. High-quality filtration of milk is one of the main parts of producing the high-grade milk consistently. By improving the grade your company can replace the milk processing plant with the one that values its suppliers and is willing to pay a good price for high-quality milk so that you will have good extra profit.

As the UVMILK® Filter is a patented invention, it has no analogous solutions; there are only low-quality fakes made of recycled polypropylene that does not filter the milk. The danger of such fakes is that they let the dirt through, capture the fat, their housing can swell, they have an unpleasant smell, the cartridge sizes vary. UVMILK® Filters are made of quality virgin polypropylene. They go through a 3-stage quality control process which eliminates any issues with cartridge wall thicknesses, along their length. A special structure of UVMILK® Filters helps them remove up to 98% of mechanical impurities from the milk, retain mastitis products and thereby decrease the somatic cell count up, reduce bacterial numbers, and retain mastitis products. This leads to the highest quality of UVMILK® filtration.