Other UVMILK® filters

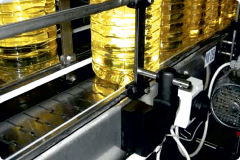

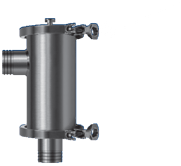

UVMilk® Oil purification filter

UVMilk® Oil purification filter

Refine industrial and cooking oil on different production stages:

- Suitable either for hot or cold press

- No oil losses during the filtration process

- Can be installed on a production line of any size

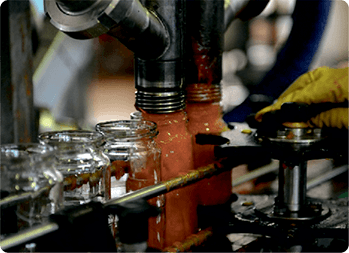

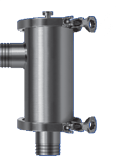

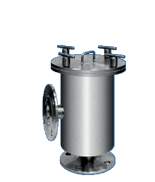

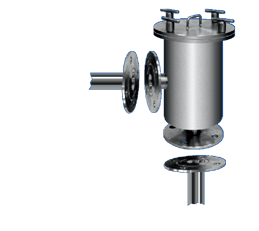

UVMilk® brine filter

UVMilk® brine filter

It is used to refine the brine from mechanical impurities

- Refine the foreign particles up to 99%

- Reduce the noise from compressor

- Can be installed on a production line of any size

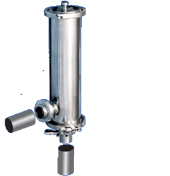

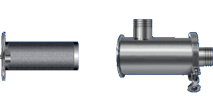

Uvmilk Netted filter

Uvmilk Netted filter

Refine the liquids from the foreign impurities during the straight line filtration process

- Reliability and air-tightness of purification system

- The filtration system is reusable; you need only to clean it after usage

- Suitable either for hot or cold liquids

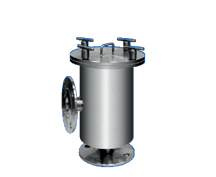

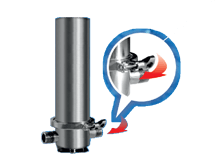

UVMilk® fuel filter

UVMilk® fuel filter

Refine the fuel from foreign impurities

- The filter housing is pressure resistant up to 20 atm

- Replacing the filter cartridge takes 1-2 minutes

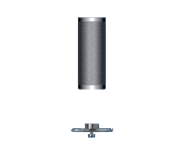

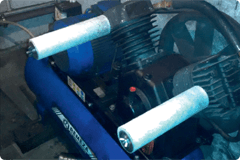

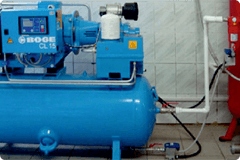

UVMilk® air purification filter

UVMilk® air purification filter

Refine the inlet air from the dust and other mechanical impurities

- The filter is able to reduce up to 99% of mechanical impurities from the air

- Reduces the noise during the working process(compressors)

- The filter cartridge UVMILK ® suits all existing air filter housings

UVMilk® aqua filter

UVMilk® aqua filter

Remove sand, rust, suspended particles, including clays, silt and other organic substances from water.

- Special, patented multilayered structure provides a large filtration area

- Can be used either in cold or hot water

- Replacing the filter cartridge takes 1-2 minutes

The filtration process is one of the most important stages in the oil production. The oil which is fabricated by pressuring method contains more than 1 % of impurities. Such as:

- cell tissue pieces

- phosphatides

- protein and mucilaginous substances

- coloring materials

- free fatty acids and others components

The majority of this impurities influence on the oil quality.

- preliminary and secondary cleaning

- winterizing

- bleaching

- hardening

Oil purification UVMilk filter is intended for sunflower oil, soya bean oil, rape oil, flax oil and others.

- An effective oil purification from mechanical impurities

- Multilayered filtration process

- Functional filter housing fastener system

- Can be installed on a production line of any size

- Suitable either for hot or cold press

- Low filtration cost

- No oil losses during the filtration process

- Minimum space requirement

- Long service life of the filter housing

- No electricity consumption

- The design conforms to international standards

The filters productivity depends on system pressure and amounts of nonoleaginous impurities in the oil.

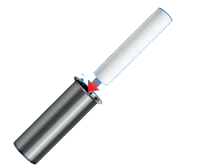

1. Open the cover

2. Insert the filter cartridge

into the cover of filter housing

3. Locate the filter

in the filter housing

4. Fix the cover of

the filter housing by clamps

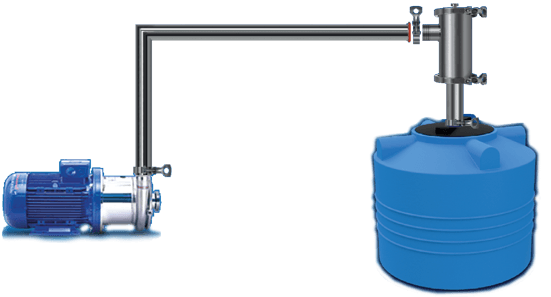

The UVMilk filter should

be installed after the pump.

a high quality product

with long shelf life!

UVMilk brine filters are widely used in the food industry enterprises in order to refine the brine from mechanical impurities. It is always used for brine preparation a low-quaility salt which contains a lot of mechanical impurities such as ground, small stones, clay etc. As a result the salt dissolves in the brine and all mechanical impurities need to be refined.

- Cheese production

- Meat products preservation

- Vegetables conservation

The filtration process is absolutely necessary on the first stage of brine usage. Moreover it is necessary to purify the used brine also because it contains cheese protein, cheese grain or other compounds which can get into the brine along with the salting products.

1. The elimination of foreign particles up to 98%

2. Absolutely safe for the brine

3. An individual approach, you can pick the filter according to your requirements

4. Individual filter mounting into your equipment

5. The possibility of the brine re-usage

6. UVMilk filters hold up aggressive environment

7. The filter housing is made of thick walled stainless steel

8. The filter is able to work during several days which minimizes the filtration expences.

After UVMilk filtration process the brine will be perfectly clean. Your customers will be satisfied with the high-quality products- cheese, meat and vegetables preserves, sour cabbage etc.

For more than 5 years a lot of diary plants, horticultural and meat preservation enterprises all around the Russian Federation have been using UVMilk brine filters!

Make a free call and get more detailed information!

UVMilk netted filter is designed especially for refining the liquids from the foreign impurities during the straight line filtration process. Our filtration system consists of two parts: filter housing made of stainless steel and filter cartridge made of stainless steel gauze for big impurities removal.

- Preliminary cleaning with the netted UVMilk filter provides more effective work of the fine mesh filter

- The reliability and air-tightness of purification system

- The filter housing and filter cartridge are easy to clean

- The filter housing material is high-quality stainless steel. That is why it can withstand high temperatures

- Compact sizes of the filter housing allow to install it in any part of technological line

- The filtration system is re-usable, you need only to clean it after usage

- You can use any cleaning chemicals

- No electricity consumption. The only requirement for our system to work is the system pressure

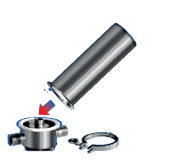

1. Open the cover

2. Insert the netted filter

into the cover of filter housing

3. Locate the filter

in the filter housing

4. Fix the cover of the

filter housing by clamps

5. The netted UVMilk filter

should be installed after the pump.

- Milk

- Water

- Fuel

- Syrup

- Oil

- Others liquids

The environment and modern diesel engines depends greatly on the fuel quality nowadays. That is why the importance of using high-quality fuel is unaccomplished. It reduces the risk of equipment failure, an expensive repairs and idle plant expenses as follows.

Moreover during the transportation, transfer or fuel storage the dirt is accumulated inside even though you are absolutely confident in your fuel supplier.

The main purifying method is a filtration process, during which the fuel is passed through the filter cartridge.

1. Spending a small amount on purchasing filters, you extends the service life of your equipment

2. You do not spend money on expensive repairs that may be necessary during the usage of raw fuel

- Effective purification from mechanical impurities

- Could be installed in any part of the fuel tube

- Easy filter cartridges replacement

- Visibility of fuel quality on the used filter

- The filter housing service life is unlimited

- The filter housing is pressure resistant up to 20 atm

- Low cost in comparison to the industrial fuel purification facilities

- Large filter cartridge capacity

- Extends the service life of your equipment

- No repair costs

- Mobility filtration unit

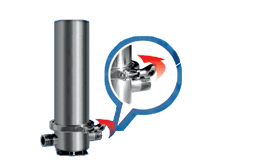

1. Open the cover

2. Insert the filter cartridge

into the slot in the cover.

3. Locate the filter

in the filter housing

4. Fix the cover of the filter housing by clamps

Housing material — stainless steel 12X18H10T

Filter cartridge material — food grade polypropylene

- At the gas stations during fuel generation and refueling

- During the fuel purchasing (at this case the filter housing should be mounted into the hose during the fuel transfer process)

- During the refueling of agricultural machinery in the fields

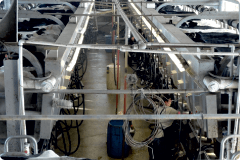

Outdoor air contains a large amount of dust which can get inside the house. The necessity of air purification appears when the content of dust and other mechanical impurities in the supply air exceeds the permissible concentration.

- The catering

- The production areas

- On poultry farms

- In cement plants

- In metal processing workshops

- On the lines of packaging / bottling

- In agricultural machinery, harvesters etc

For example, the polluted air can be presented in dairy plants during the packaging process. Further, this air can get into the milk package.The milk is very sensitive to different mechanical impurities, as it is a positive environment for the bacteria growth.

As a result, the milk sours.

The same situation may occur in the beverages, beer, juice bottling lines etc.

The air purification process is based on filtering the processed air through the porous surface during which the solids are retained and the clean air completely passes through. ФUVMilk air filter can be also installed into compressors where it prevents the dust and other impurities from getting into.

- The filter is able to reduce up to 99% of mechanical impurities

- The filter cartridge is functional

- Reduces the noise during the working process(compressors)

- Increases the uniformity of the air flow

- The filter cartridge UVMILK ® suits all existing air filter housings /li>

UVMilk air filter is customizes which means that it is produced according to your individual requirements.

Moreover UVMilk air filters can be used also for gas purification.

Water treatment is one of the most important tasks in industrial production. Typically, the service water contains large amounts of mechanical impurities which fall into the water from the pipeline network, formed and accumulated during the process of installation, operation and repair of pipelines.

- The accumulation of dirt in the ordinarily thread slots influences greatly the final product quality. That is why the clamp connection used in our filter housings helps to prevent such situations

- Up-to-date system of water purification from mechanical impurities without chemicals

- Special, patented multilayered structure provides a large filtration area

- Due to the multilayered structure the aqua-filter is high in productivity

- The filter housing is made of stainless steel and has long warranty period.

- Easy to install and maintain

- Replacing the filter cartridge takes 1-2 minutes

- Can be used outdoors at above zero temperatures

- Can be used either in cold or hot water

- Low price in comparison to the industrial water purification plants

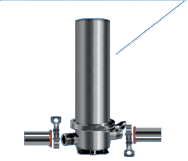

1. Open the cover

2. Insert the filter cartridge into

the cover of the filter housing.

3. Locate the filter cartridge in the filter housing.

4. Fix the cover of the filter housing by clamps

5. The filter is ready for work!

- Filter mesh size — 10 mkm

- Max pressure — 8 atm

- Recommended pressure — 2,5 atm

- Max water temperature — 100°С

- Weight — 2,5 kg

- The filter housing service life is unlimited.

- The productivity of one aqua- filter cartridge is from 50000-500000 liters*

- * — The amount of water depends on the initial quality

E-mail:

uv@uvmilk.com